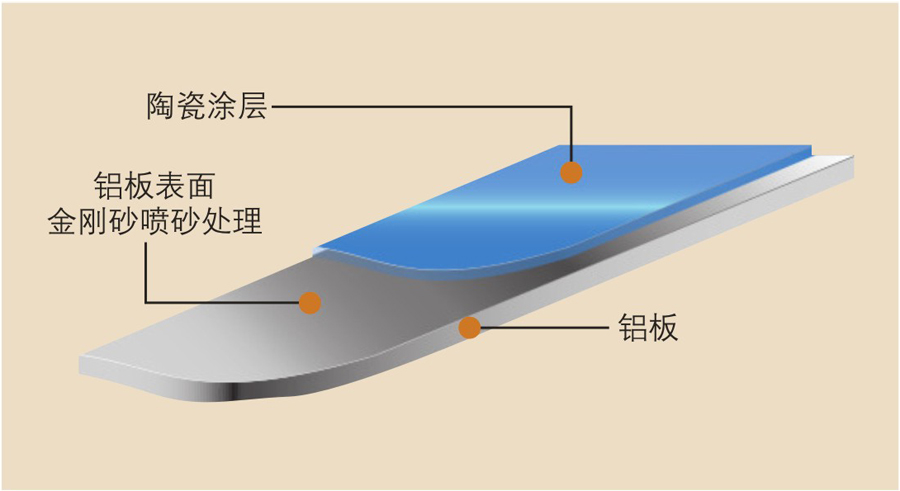

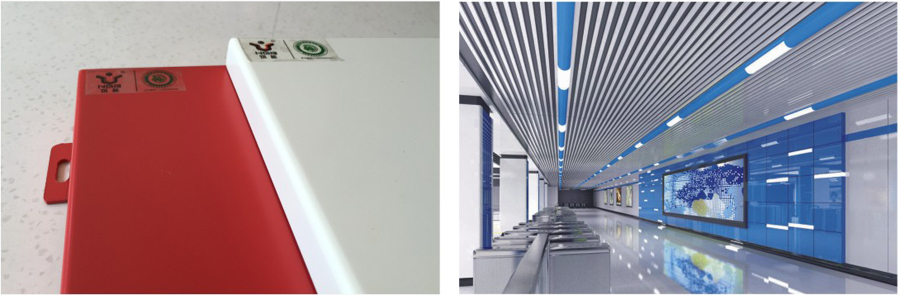

烤瓷铝板成膜物质主要是二氧化硅,在低温(200℃左右)下成形为类似玻璃、搪瓷的涂层;成膜后,涂层本身可耐受1400℃高温;将涂层涂覆在铝板上统称为烤瓷铝板。主要用于轨道机车内壁,地铁站、机场、火车站等公共建筑领域。在发生火灾时不产生任何有毒气体释放,大大降低了火灾给人们带来的危害风险。同时烤瓷板具有较低的表面张力特性(表面张力22-23达因),具有A1级防火性能、良好的抗划伤性能、优异的耐候性能等优点。

The film-forming substance of porcelain aluminum plate is mainly silicon dioxide, which is formed into a coating similar to glass and enamel at low temperature (about 200℃); After film formation, the coating itself can withstand high temperature of 1400℃. Coating on aluminum plate is collectively referred to as porcelain aluminum plate. It is mainly used in the field of public buildings such as railway locomotive inner wall, subway station, airport, railway station, etc. When a fire occurs, no toxic gas is released, thus greatly reducing the hazard risk brought by the fire to people. At the same time, porcelain plates have lower surface tension characteristics (surface tension 22-23 dynes), and have the advantages of A1 grade fire resistance, good scratch resistance, excellent weather resistance, etc.